HHO Kit HSL 3000

From 219,00 €

Basic HHO Kit for Petrol or Diesel engine

Suitable for engine displacement: from 2000cc to 3000cc

Includes water level sensor and automatic fuse 30A

- Description

- Technical Data

- Package Contents

- Additional information

Description

Strong advantages of our HHO kit

HHO gas production – Despite its compact size (10 x 10 x 11 cm.), the cell is relatively small in proportion to the quantity of gas production, ensuring optimal operation during all engine loads and its RPMs

The materials we use to create and produce our #HHO kits and systems are all Quality certificated.

The Stainless Steel plates we use are 316L – INOX with a higher nickel content, which is the steel’s rust-resistant component. All the Stainless steel plates are laser cut with very high precision. Besides, the stainless steel plates passed through chemical and mechanical treatment, allowing us to extend the working surface and longer work life.

We make our own gaskets of EPDM rubber made with a special recipe of components to meet our technical requirements. Such as temperature range between -50 to + 170 degrees. Furthermore, EPDM rubber is oil-resistant and in a square shape, which allows us to use more working surfaces for each Stainless steel plate. The thickness of the gaskets is proper for the electrons’ normal conductivity process between plates with a proper electrolyte ratio. It is crucial for the #HHO generator’s normal operation during temperature amplitudes like tough winter or sweltering summer.

The hose connectors we use are the “Push-In” model, thus allowing you to plug the hose into the connector, and that’s all. Furthermore, the Push-In connectors are 360 degrees movable from their base to allow easy installation. They are made in Europe, not China! We use only PA12 hose, due to its high quality, instead of PVC, nylon, silicone, or a garden hose, which are not reliable.

We produce our own #HHO reservoir with a volume of 1.4 liters from fire retardant plastic to meet the automobile industry’s requirements! Such as durability, long life, and compact size that would be easily installed in all cars. Our reservoir allows installing a #water-level sensor to add to your order during the order process, and it will come installed in your reservoir. The reservoir has a non-vented cap with a secure gasket inside that guarantees no electrolyte leaks or #HHO gas.

The reservoir’s function is to keep more electrolytes in the system and circulate the electrolyte between the Dry cell and the reservoir. When the #Hydrogen is produced by the #dry cell, water vapor is produced as well. Water vapor may carry microparticles from the electrolyte, which may cause corrosion, so the connector through which the gas is returned to the reservoir is on a lower level. Hence, the produced #HHO gas bubbles through the electrolyte, and the #hydrogen is cleaner from steam or any other particles. This is the first stage of cleaning the gas, but it is not enough for us, and we always use a secondary bubbler for more security!

The Bubbler has four functions. The first function is to clean the #HHO gas totally from steam and feed only clean gas to the air intake. The second function is to prevent reverse spark to the system’s reservoir, and the bubbler acts as a flashback arrestor. The third and most important function is to determine the water level inside the bubbler. If you drive long distances, for instance, and hold there more water vapor, the water inside will go higher level and could go to the air intake probably into the cylinders.

Imagine if water goes to your engine what it will cause?! Therefore we put a small pipe coming from the bottom of the bubbler. It goes next to the bubbler’s sidewall and goes up to a certain height, so from this pipe, the extra water will drop down, but it will also determine the water level inside the bubbler and prevent the overflowing of water to the air intake.

The fourth function is that the same pipe is sucking air through it when you rev the engine at very high RPMs, releasing the huge vacuum you have from the air intake and preventing the sucking of water into the air intake. Only we offer such a secure bubbler!

During the #HHO generators’ design, we were guided by fundamental factors such as high efficiency, performance, compact size, strength, quality, long life, easy installation, and last but not least, a good vision.

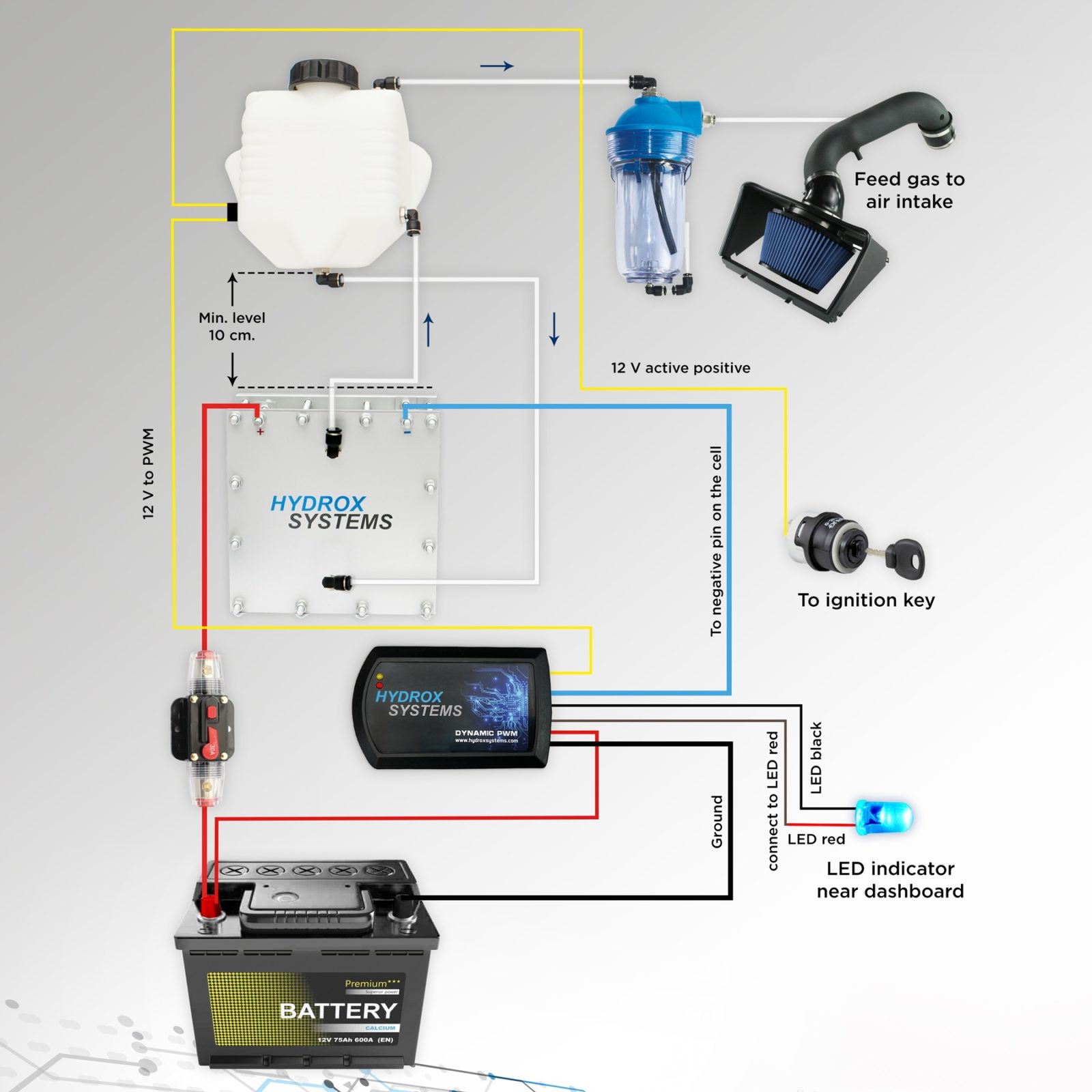

We recommend you to use #Dynamic PWM for petrol or diesel engine to control the amperes and the production of hydrogen depending on the RPMs of your vehicle!

Secondary elements of the HHO systems, like a tank, bubbler, and #Dynamic PWM, are manufactured following the requirements of compactness, strength, stability throughout a temperature, stability of chemical bases, quick and easy installation, and most importantly, consistency and certainty in connection with the cell.

We do not use relays, one-way valves, and other nonsense redundant items in our systems because the relay is integrated into the #Dynamic PWM, and it is made a much more reliable Start-Stop function and because the one-way valve is always open during the engine work. There is a vacuum, which is opening the valve!

All our HHO Products, such as HHO Generators, HHO bubbler, HHO reservoir, and HHO electronics, and all of its components, are designed and produced in the European Union. They comply with all standards required for such products!

Technical Data of the HHO Generator

Dimensions of the HHO cell: 100 mm x 100 mm x 110 mm (incl. the connectors)

Voltage: 12 – 14.4 VDC (from vehicles battery)

Material: steel INOX 316L SS

Configuration of the plates: – NNNN + NNNN – NNNN + NNNN –

(+ positive, N-neutral, – negative)

Amperage: 3 to 30 Amp

Working surface: 1300 sq. cm

Capacity: up to 1.3 liters gas per minute @ 20 amps

The required ratio of the electrolyte (water-KOH): 5%-15%

Hose connectors: Push-In type

Package includes:

HHO Dry cell -1 pc.

HHO tank/reservoir 1.4 liter – 1 pc.

HHO bubbler – 1 pc.

tubing – 4m.

Wires:

Red 6 sq.mm. – 3.00 m

Black 6 sq.mm. – 2.00 m

Blue 1.5 sq.mm. – 3.00 m

Automatic fuse – 30 amps -1pc.

Inlet gas connector – 1pc.

All electrical connectors

Installation instruction + scheme

Instructions for use

Additional information

| Weight | 4,50 kg |

|---|---|

| Dimensions | 40 × 33 × 20 cm |